Our Relationship-Based Business Model

What is Supply Chain Management?

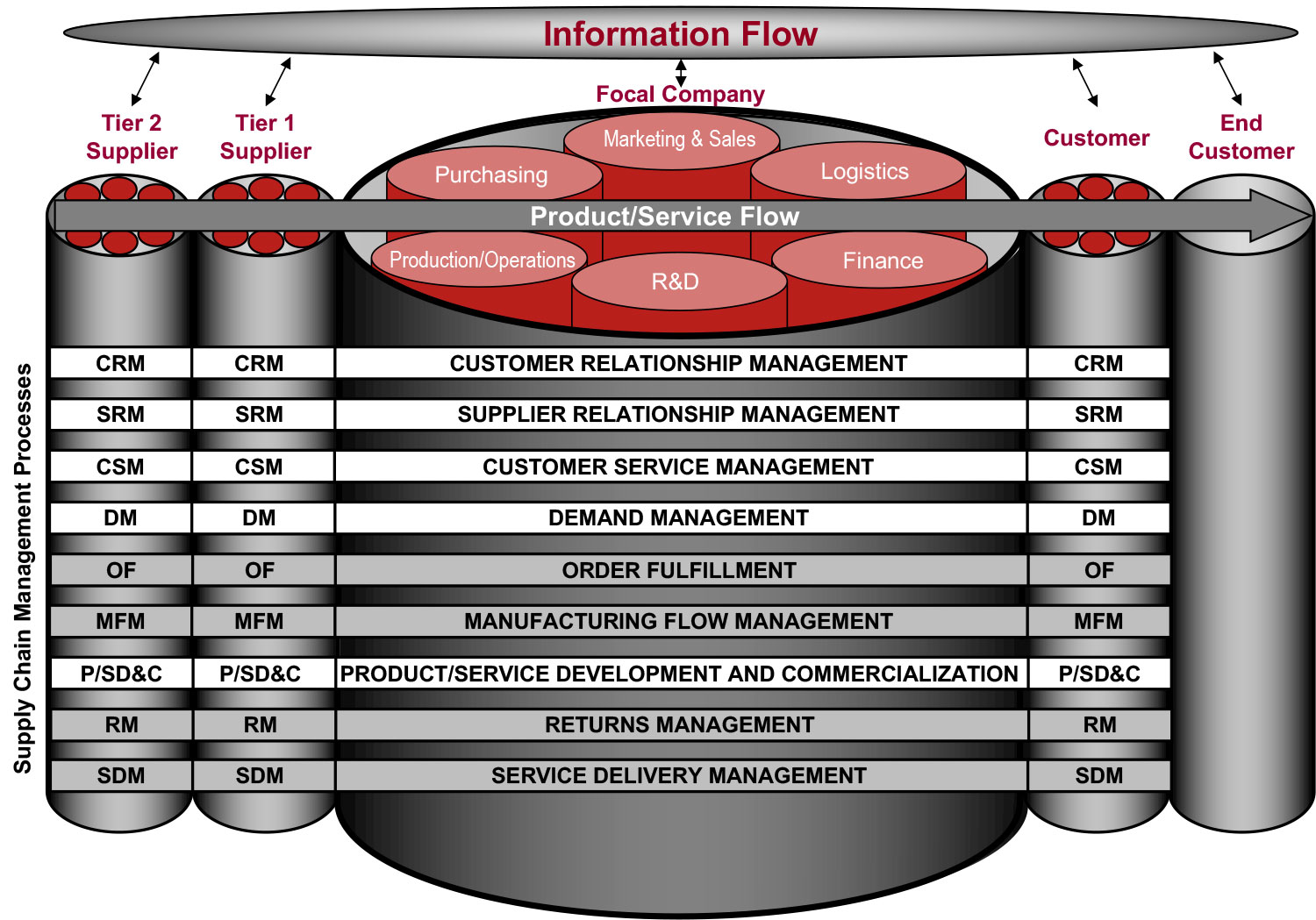

Supply chain management is the management of relationships in the network of organizations, from end customers through original suppliers, using key cross-functional business processes to create value for customers and other stakeholders.

Processes

Thousands of activities are performed and coordinated within a company, and every company is by nature in some way involved in supply chain relationships with other companies. Our research has led to the conclusion that the structure of activities within and between companies is critical for superior supply chain performance. Successful supply chain management requires integrating business processes with key members of the supply chain. Valuable resources are wasted when supply chains are not integrated, appropriately streamlined, and managed. The value of having standard business processes in place is that managers from different organizations in the supply chain can use a common language and can link-up their firms’ processes with other members of the supply chain, as appropriate.

The framework described in this book is built on nine key business processes that are both cross-functional and cross-firm. Each process is managed by a cross-functional team, including representatives from marketing and sales, logistics, production, purchasing, finance, and research and development. While each process will interface with key customers and suppliers, the customer relationship management and supplier relationship management processes form the critical linkages in the supply chain.

Supply Chain Management

Integrating and Managing Business Processes Across the Supply Chain

Copyright 2025, Supply Chain Management Institute

Partership

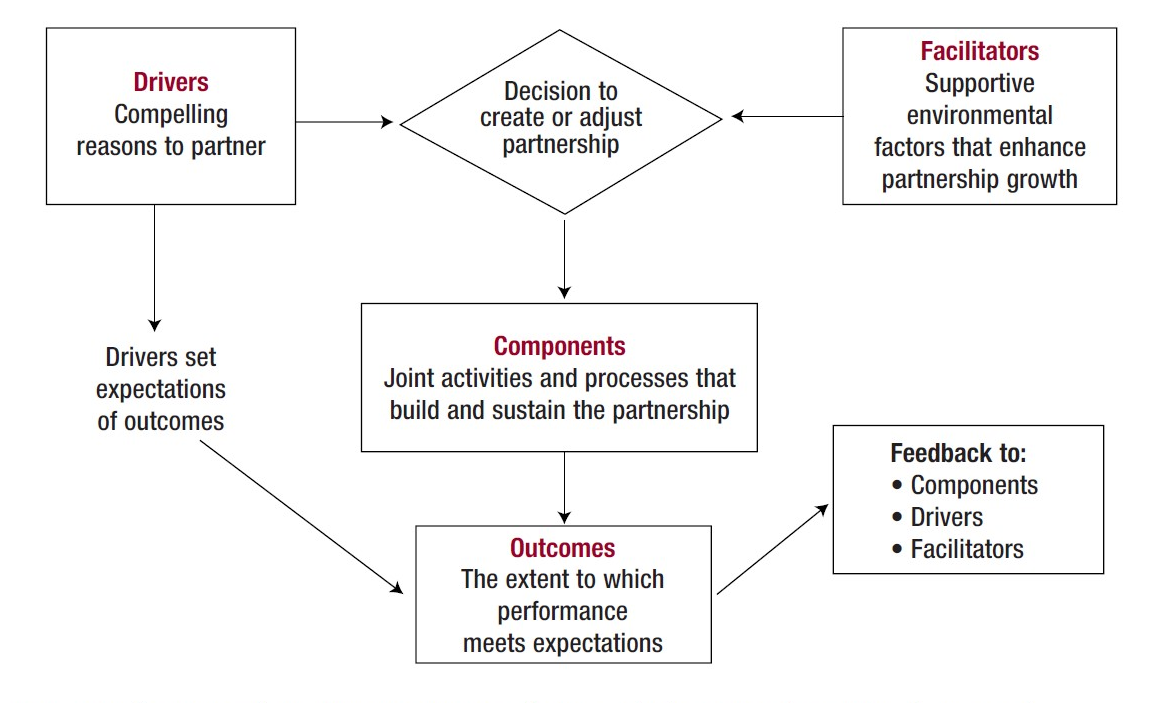

A partnership is a tailored business relationship based on mutual trust, openness, shared risk and shared rewards that results in business performance greater than would be achieved by the two firms working together in the absence of partership.

The Partnership Model

Copyright 2025, Supply Chain Management Institute

An important aspect of implementing supply chain management is the formation of appropriate linkages between members of the supply chain. While practitioners and academics have championed the value of partnerships for this purpose, the challenge is to find effective methods for developing the appropriate type of relationship. In an increasingly competitive business environment, executives are turning to partnerships to strengthen supply chain integration and provide sustainable competitive advantage. Partnering provides a way to leverage the unique skills and expertise of each partner and may also “lock-out” competitors.

Partnerships, however, are costly in terms of the time and effort required. Consequently, executives cannot and should not partner with every customer, supplier, or third-party provider. It is important to ensure that scarce resources are dedicated only to those relationships which will truly benefit from a partnership. Yet, many organizations become involved in relationships that do not meet management expectations and/or which end in failure. How can managers determine, in advance, if a potential relationship is one which will result in competitive advantage, and is worthy of the time and resources needed to fully develop into a partnership? Further, all partnerships are not the same. How does management know what type of partnership would provide the best pay-off? These questions may be answered by utilizing the partnership model presented in this book.

The Partnership Model represents a systematic process for developing, implementing and continuously improving corporate relationships. Without a foundation of effective relationships, efforts to manage the flow of materials and information across the supply chain are likely to be unsuccessful. Partnering between firms is one way to find and maintain competitive advantage. The Partnership Model provides a structured and repeatable process to effectively and efficiently build and maintain tailored business relationships that may become an asset for executives looking for competitive advantage. One example is the Wendy’s and Tyson relationship, which was the basis for a 2004 article in Harvard Business Review. You can also read about the Partnership Model in Chapter 4 of the Supply Chain Management book.

Performance

Most of the performance measures called “supply chain metrics” are nothing more than logistics measures that have an internal focus and do not capture how the firm drives value or profitability in the supply chain. These measures may actually prove to be dysfunctional by attempting to optimize the firm’s performance at the expense of the other firms in the supply chain, an approach that eventually decreases the value of the entire supply chain.

It is generally believed that a well-crafted system of supply chain metrics can increase the chances for success by aligning processes across multiple firms, targeting the most profitable market segments, and obtaining a competitive advantage through differentiated services and lower costs. Inappropriate metrics, on the other hand, will result in failure to meet customer expectations, sub-optimization of departmental or company performance, missed opportunities to outperform the competition, and conflict within the supply chain.

We provide a framework for developing supply chain metrics that translates performance into shareholder value. The framework focuses on managing the interfacing customer relationship management and supplier relationship management processes at each link in the supply chain. The translation of process improvements into supplier and customer profitability provides a method for developing metrics that identify opportunities for improved profitability and aligning objectives across members of the supply chain. By understanding the profitability at each link, management, over time, can make decisions that maximize performance for the supply chain.